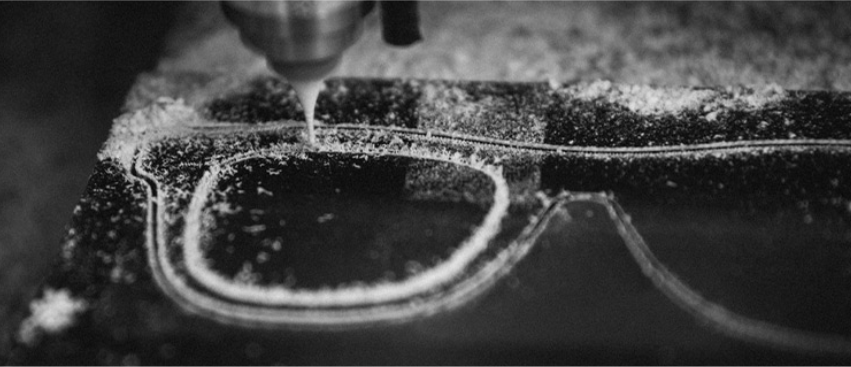

The McGee Group manufactures and distributes eyewear under nearly a dozen brand names.

The company specifically partners with brands that take giving back seriously, and endeavors to do the same. Despite the diversity of causes supported – from breast cancer research, to wildlife conservation – they share an important trait with McGee itself: a profound sense of urgency. Millions of people rely on eyeglasses to improve their vision, and McGee Group provides fast, reliable distribution, whether to some of the world’s largest eyewear retailers or small, local eyecare professionals.

With rapid, accurate, and cost-effective distribution in mind, McGee began searching for a shipping software solution to connect to its Sage X3 ERP. McGee ultimately selected 3G Pacejet Shipping because of its ability to enhance well-established workflows, rather than forcing the company to adopt new ones.

The McGee warehouse uses a very packing-centric shipping process, which led to discovering just how easy Pacejet was to build connections into. Sage X3 is a favorite among companies that like to configure their ERP around their businesses, instead adopting ERP-specific business best practices, and aren’t afraid to put in the work. Impressed with the off-the-shelf Pacejet-X3 connector, the team began asking itself whether there were ways to further reduce the time needed to ship an order. The answer was a resounding “yes” and to the tune of up to 5-7 minutes per order by aligning data and fulfillment processes.

Rather than have to look for workarounds, or alter established processes, the team simply used the Pacejet API to build its own connector, optimized to its packing process. With other software this type of build would typically take weeks, require substantial support, and rarely work right the first time. However, thanks to the Pacejet API design, the new connector was talking to Pacejet in a day and optimized to X3 a week later, based solely on the provided documentation.

This led to a lengthy quality control process – sometimes taking 10-15 minutes per package – to ensure accuracy. However, with Pacejet’s Scan Packing, the entire QC process was eliminated. Thanks to the speed, accuracy, and feedback from scanning, the packing process was reduced from minutes to seconds, and only required one person – the packer – to handle both QC and packing (not the two people previously required when the processes were separate.

Success with Pacejet was about more than the nuances of McGee’s own processes, but those of its customer base, too. The world’s largest brick & mortar and online retailers, and small, local eyecare professionals, differ vastly from one another, but McGee needed to be able to ship to both.

Beyond improving speed and order accuracy, the settings in Pacejet proved ideal. For example, things like allowing the customer service teams to designate a specific carrier or service, select the absolute lowest cost provider, and insert the customers’ own carrier account numbers. Flexibility, without the need to deviate from established processes, or losing momentum, plays a key role in maintaining the culture of efficiency McGee is known for.

Each order processed by McGee Group represents multiple layers of dedication: Dedication to the customers who trust MgGee to supply their inventory. Dedication to the consumers, who rely on McGee’s products to improve their vision. And dedication to the causes that the company supports, both directly and indirectly, through its business. As a company, McGee takes each of these responsibilities very seriously, and therefore remains committed to always using the tools that will help it fulfill at every level.

“Everyone has something they do best – it’s just a question of recognizing and supporting that. We have a great fulfillment team, and we support that team by providing tools – like software – that make each member’s jobs easier. 3G Pacejet Shipping was part of that: it respects their workflows, could be learned in minutes, and eliminated time-consuming processes. Most importantly, the better we support our team, the better we can support our partners, such as the eyecare professionals who fit our glasses to consumers and brands we work with in support of mutually important causes.”